- Block Control System(BCS)

- Equipment Automation Program(EAP)

- Equipment Collection Mate(ECM)

- Rabbit Service Bus(ESB)

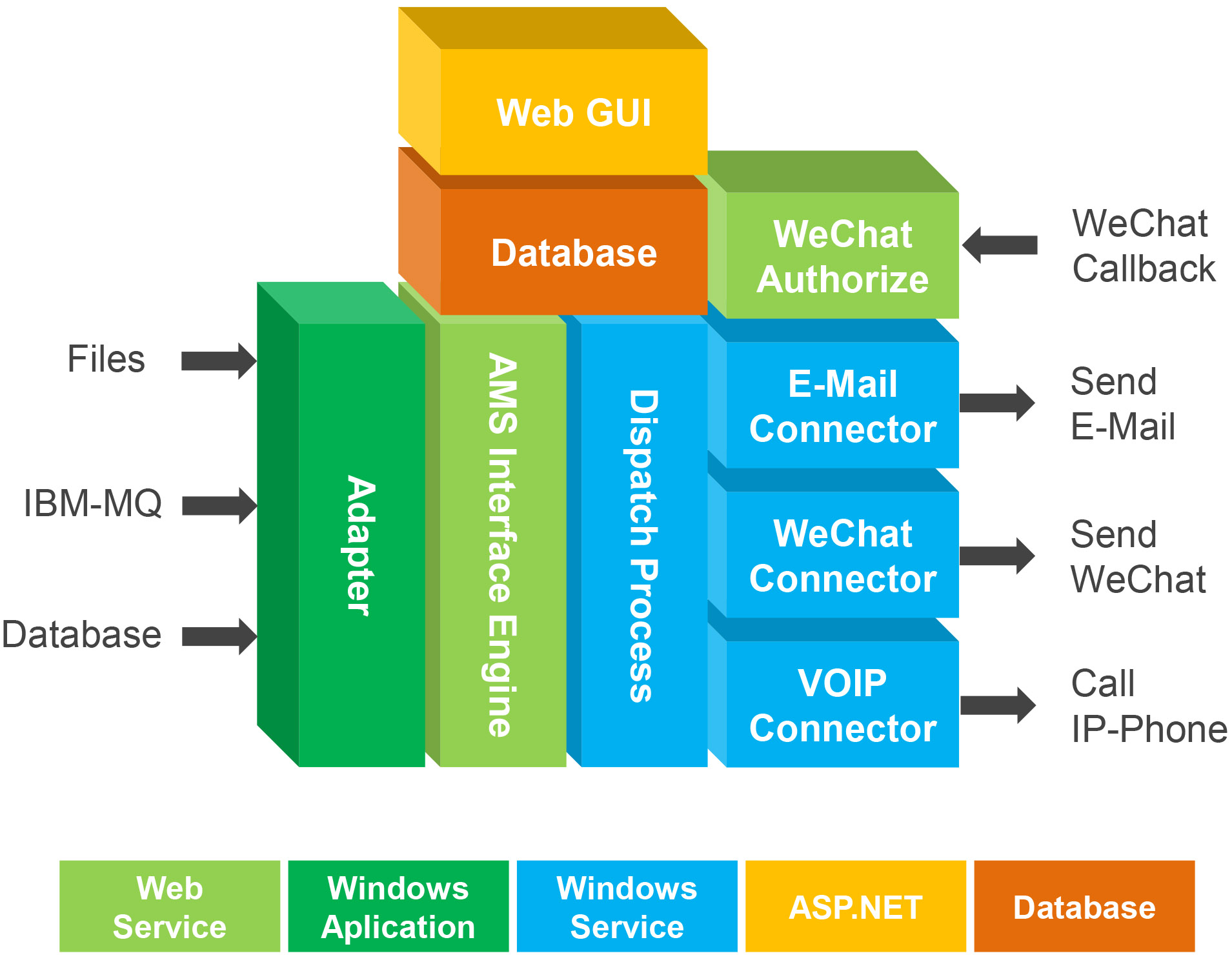

- Alarm Management System(AMS)

- Fab Monitor System(FMB)

Message Manager

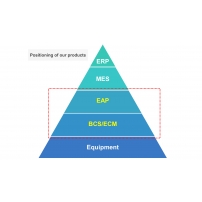

- ERP:利用有效的管理模式,利用現代化的科學技術,有效的整合企業內部的資源,最大限度的降低生產成本,有效提高企業的生產效率。

- MES:在產品從工單發出到成品完工的過程中,製造執行系統起到傳遞信息以優化生產活動的作用。

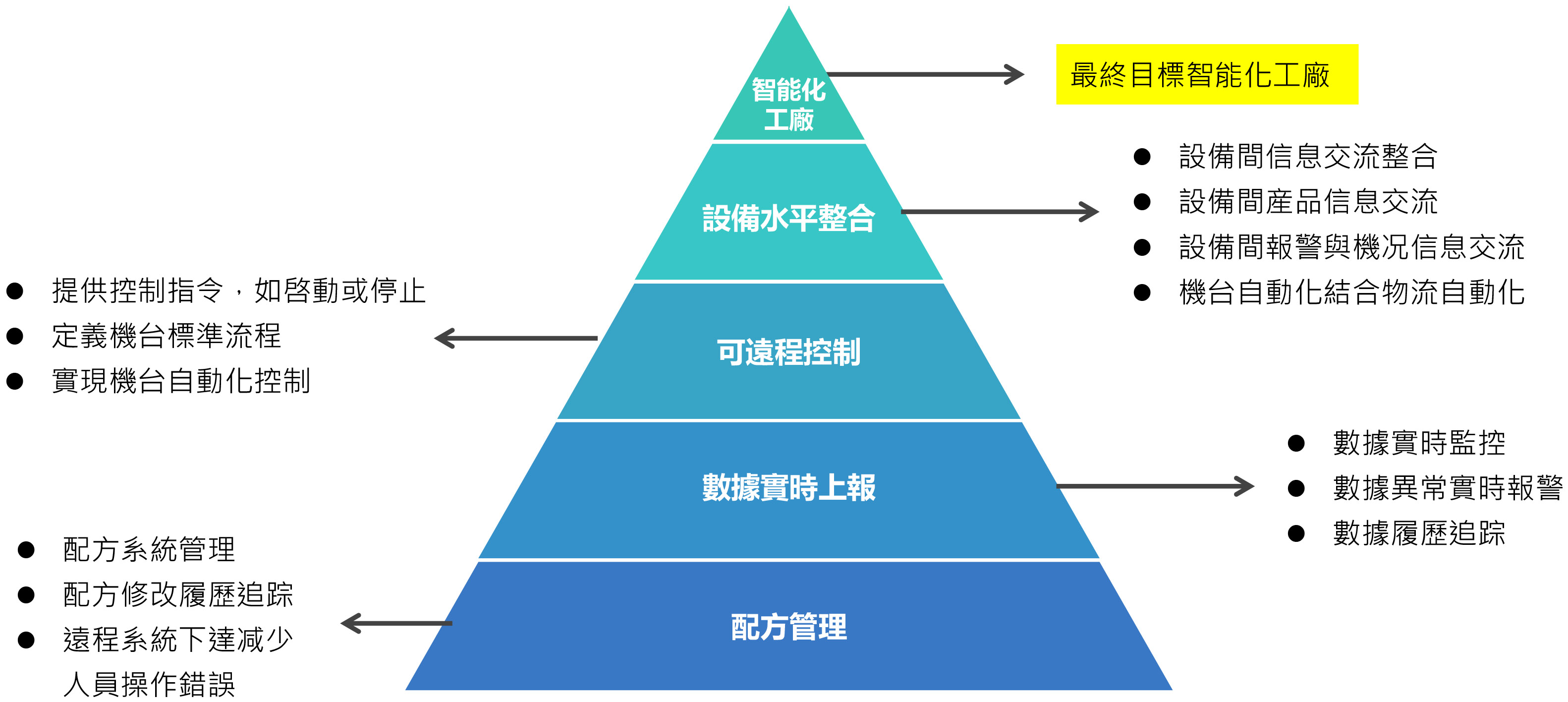

- EAP: 工廠自動化系統程式之一,讓排程派工有所依據,提高機台使用效能,降低成本提高機台生產率。提供一完整自動化方案,在機台連線下,協助減少人為在量產時的疏失,提高產品良率,達成無人工廠的最終目的。

- BCS/ECM: 負責監視、控制機台的狀態,並管理產線或是機台內的在製品(WIP)資料,提供與下位機台和上位系統的資料整合方案。

- Equipment: 智能化機台設備,其中包括Inline Equipment, Standalone Equipment,檢查機、量測機,製程機台,與搬運設備。

Multi-Thread Event Trigger

.jpg)

- Message Event by Connector or Service.

- Message-Dispatching raise a thread do Service Method.

- Service base on Entities to handle business flow.

- Service send a Message to PLC connector for data download or response.

- Service send a Message to MES connector for report or request.

- Connector, Service, System logging separate.

- Formatting History depend on ORM Object save to database.

- Equipment, Port, Job status update to Entities, and mapping to Entities XML files.

Key Features

.jpg)

Equipment Management

.jpg)

.png)

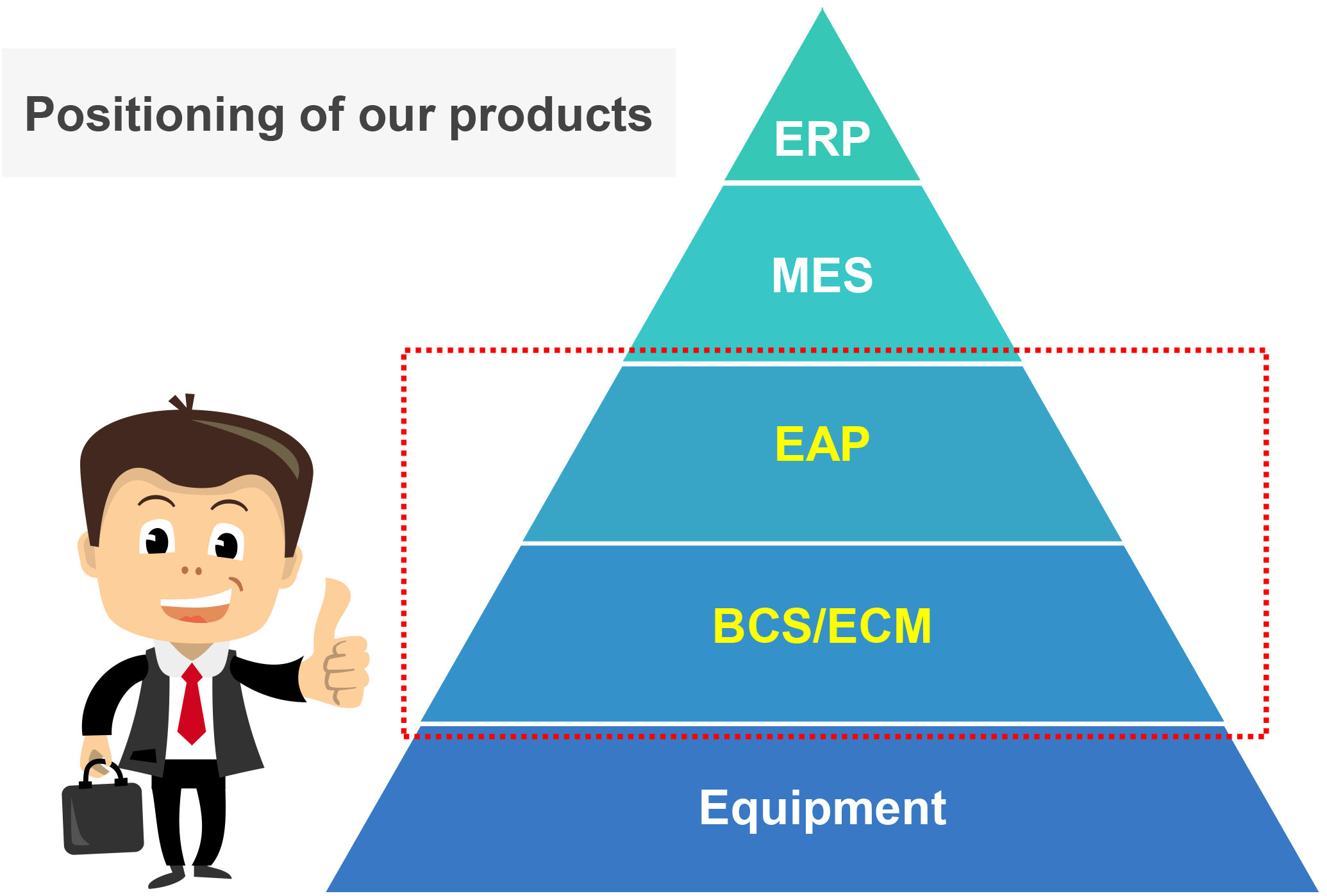

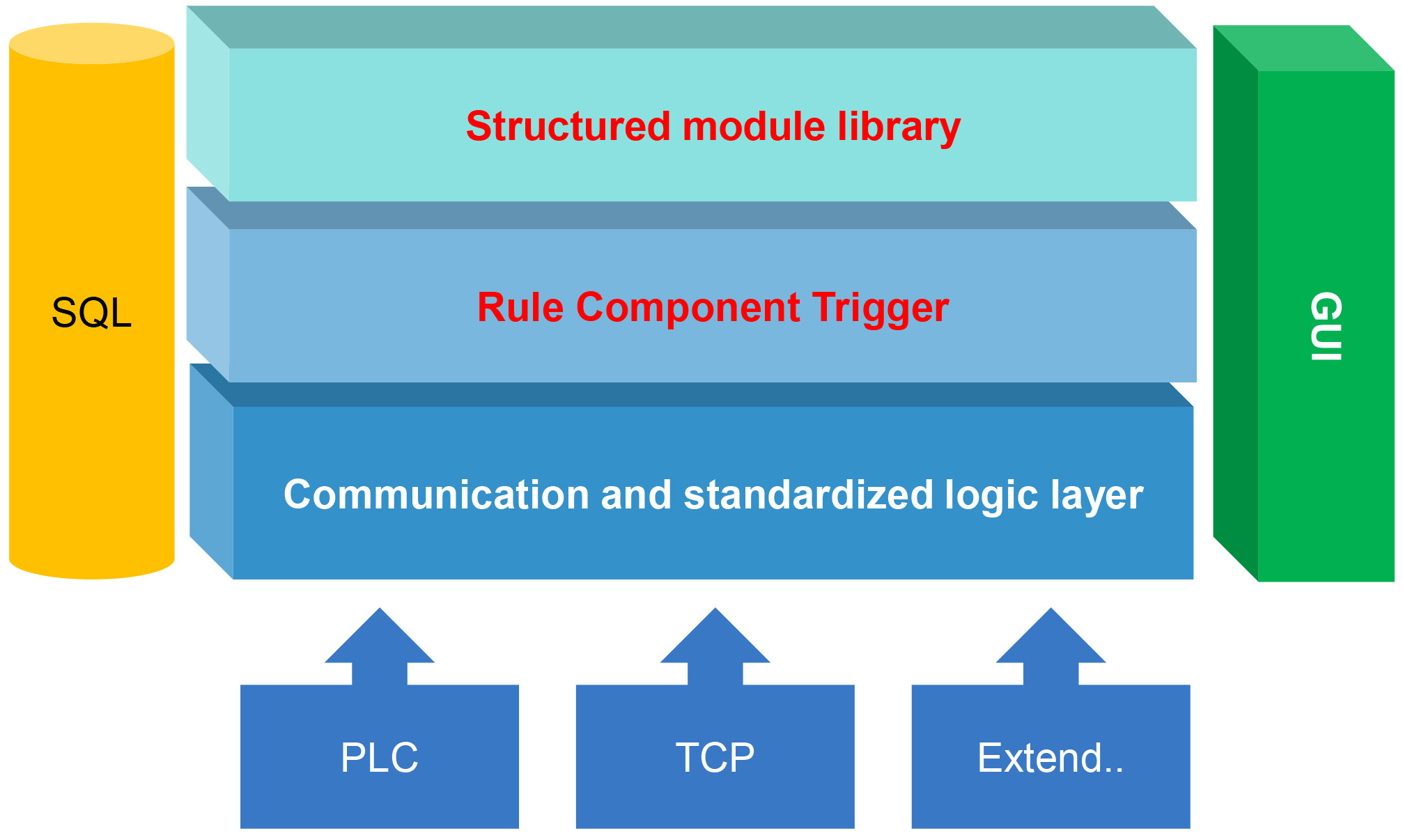

EAP軟體架構

.png)

SECS/GEM Features

.jpg)

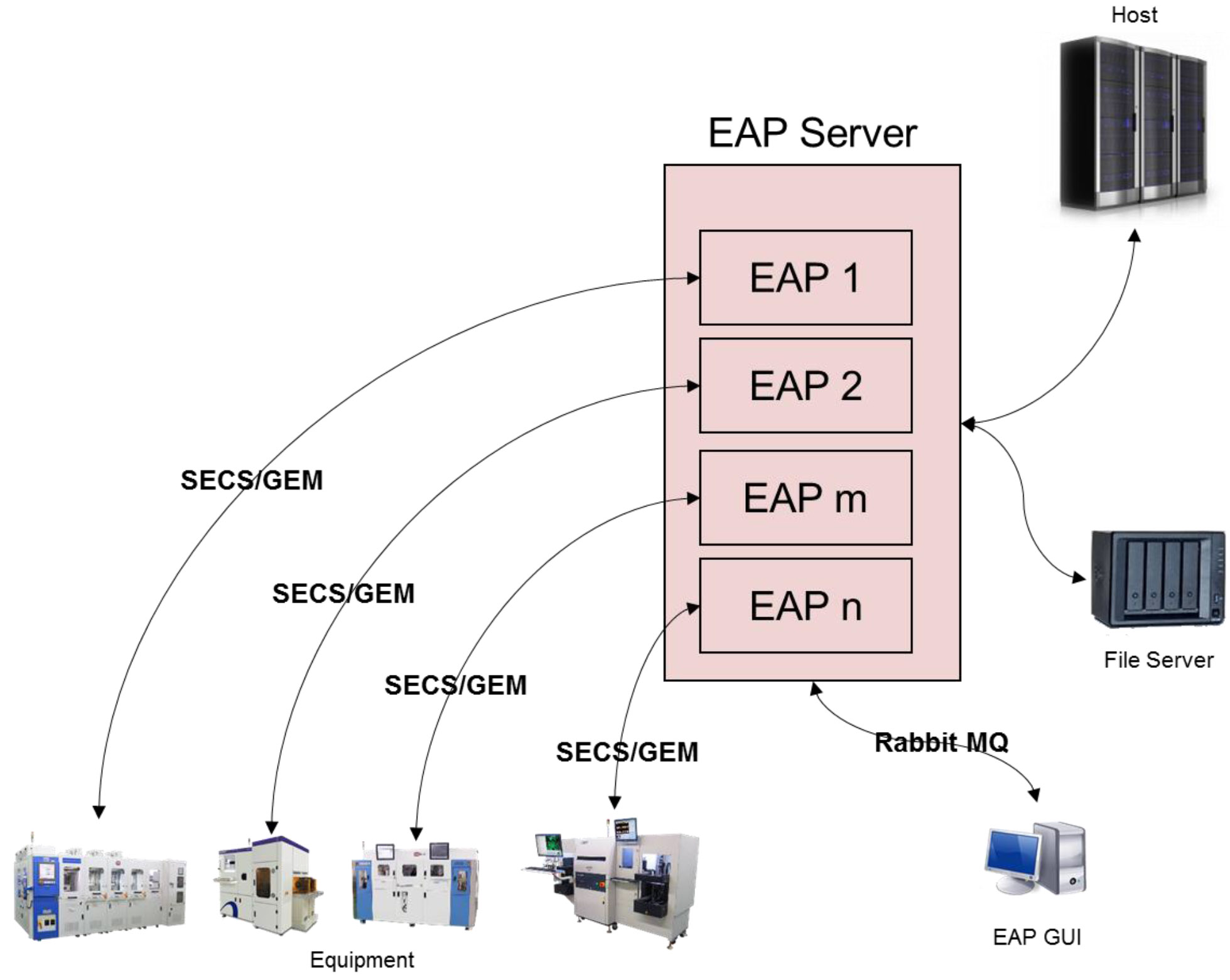

Recommend System Architecture

EAP build system Architecture

- The EAP server can be a physical machine or a virtual machine(such as VMWare, Hyper-V).

- Recommend an EAP Server can install 10~20 EAPs depends on the server ability.

- A EAP can communication a inline equipment by SECS/GEM.

ECM軟體架構

.png)

預期為客戶帶來的效益

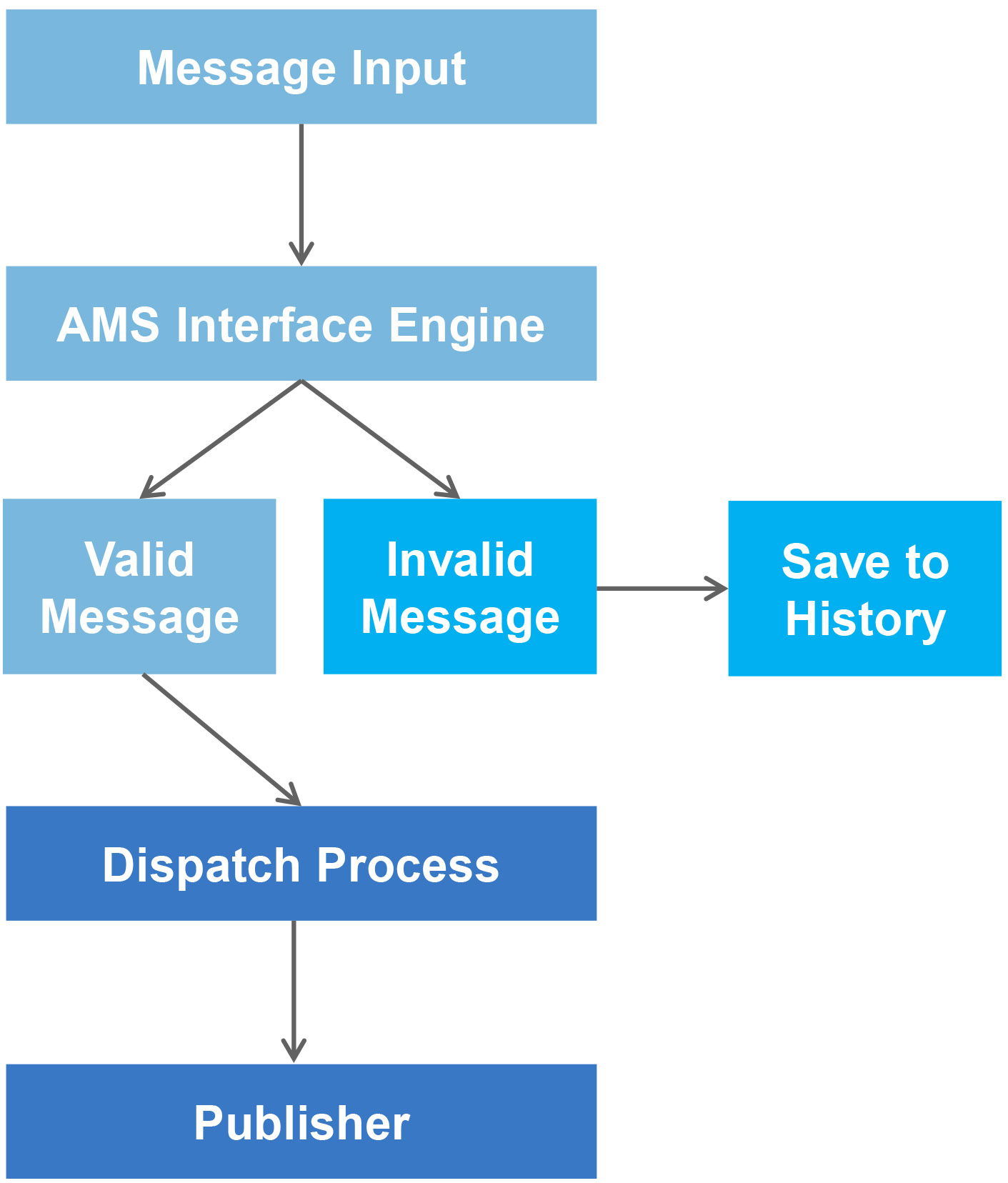

AMS軟體架構

.png)

Interface for Input/output

.png)